ROM

RUS

ENG

<

>

<

>

<

>

<

>

<

>

<

>

<

>

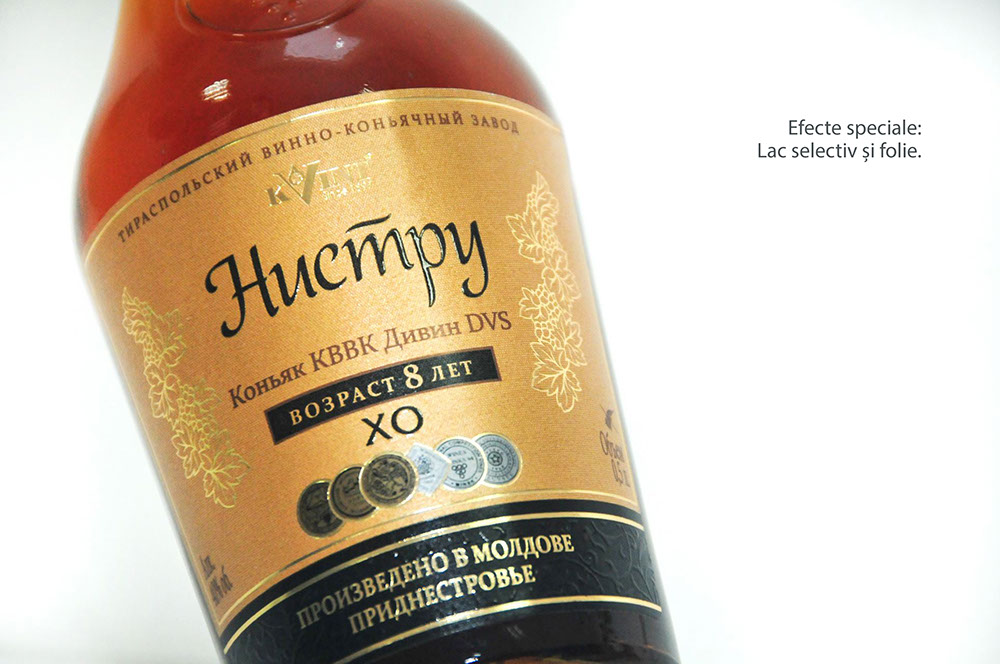

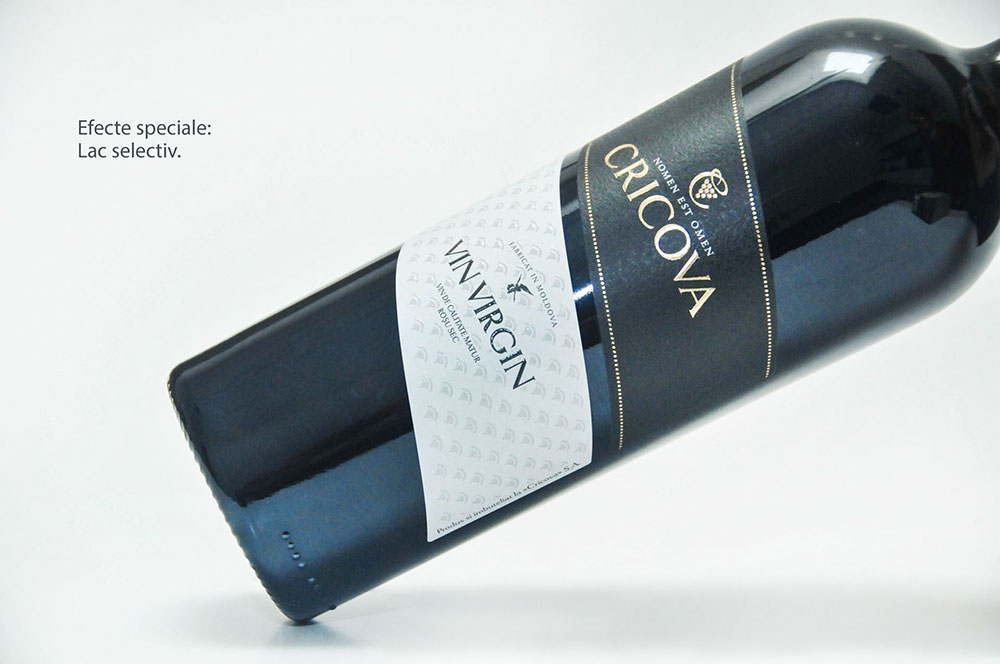

Labels

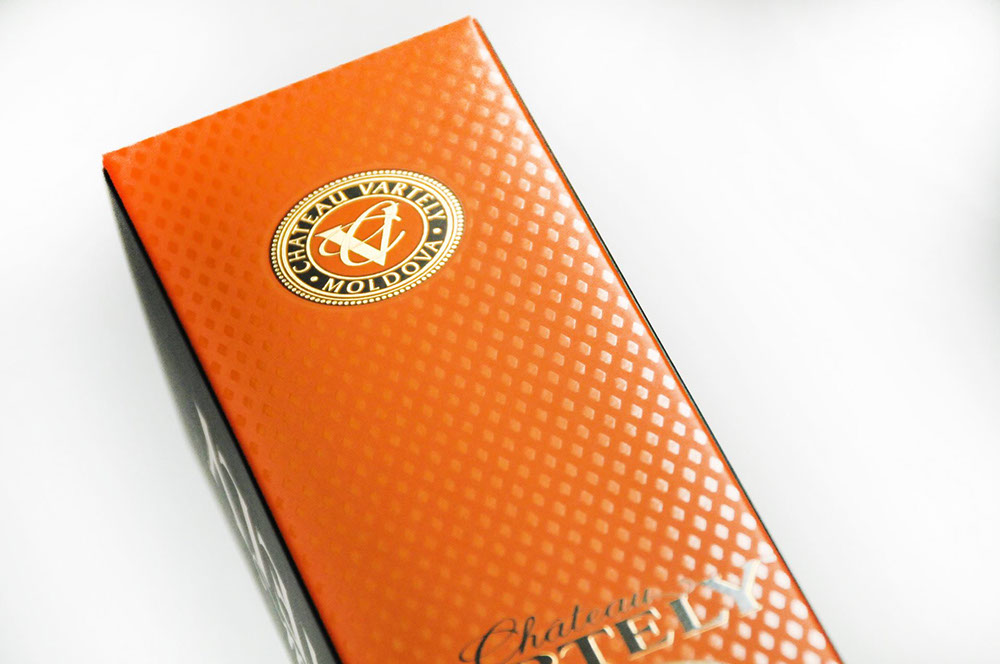

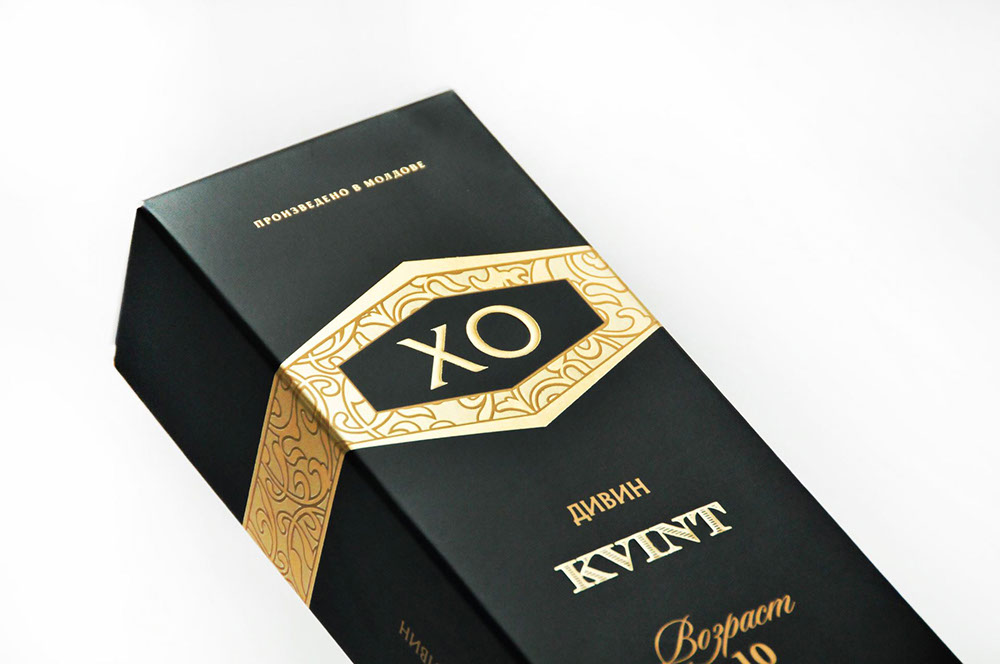

Boxes

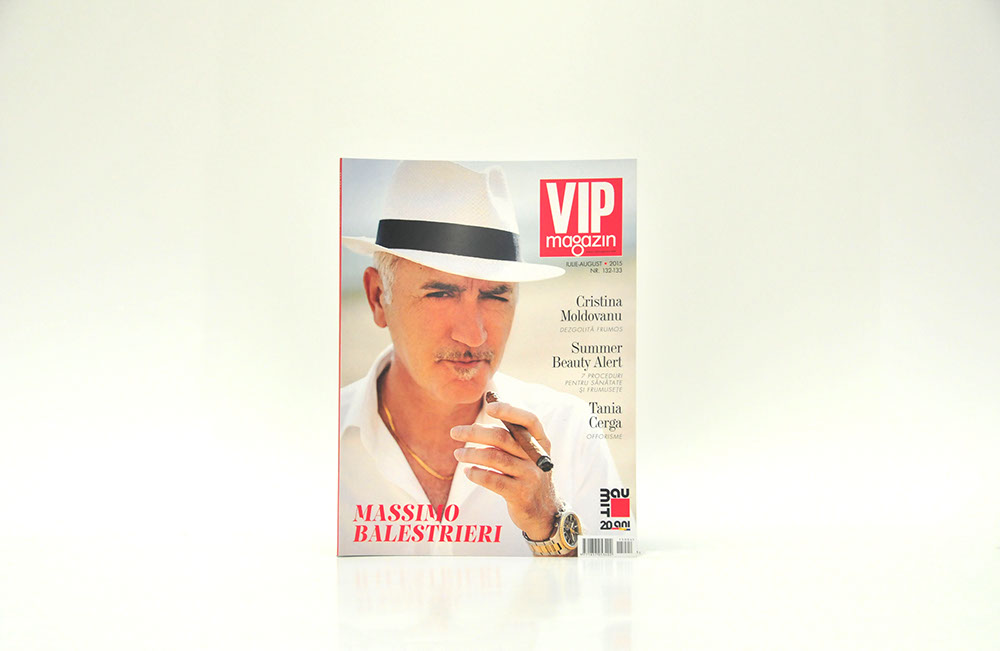

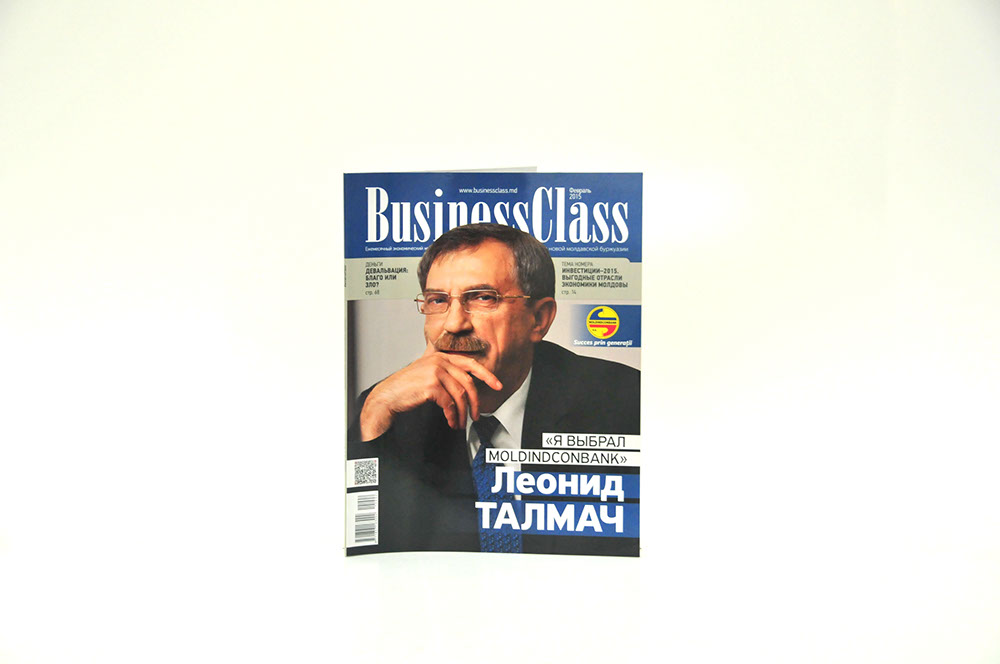

Magazines

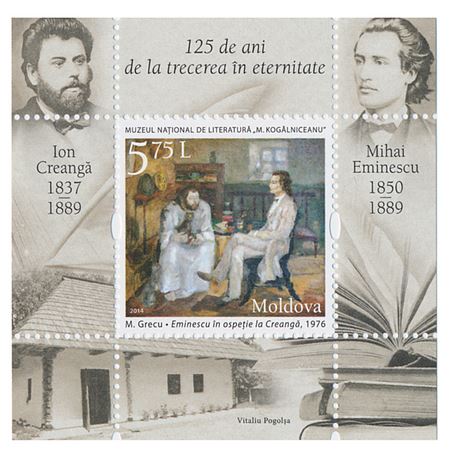

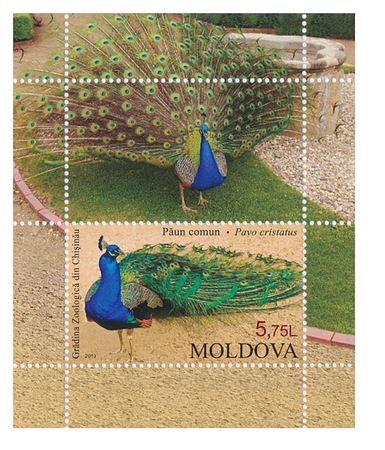

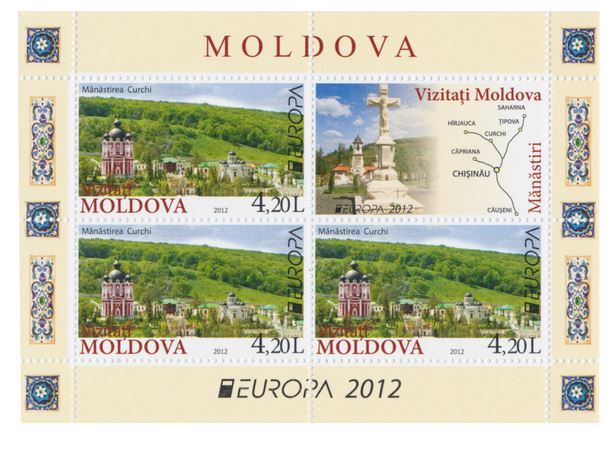

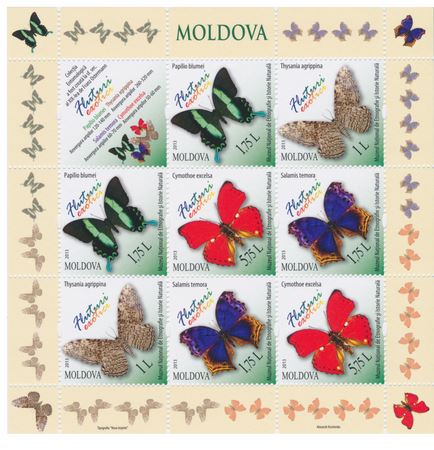

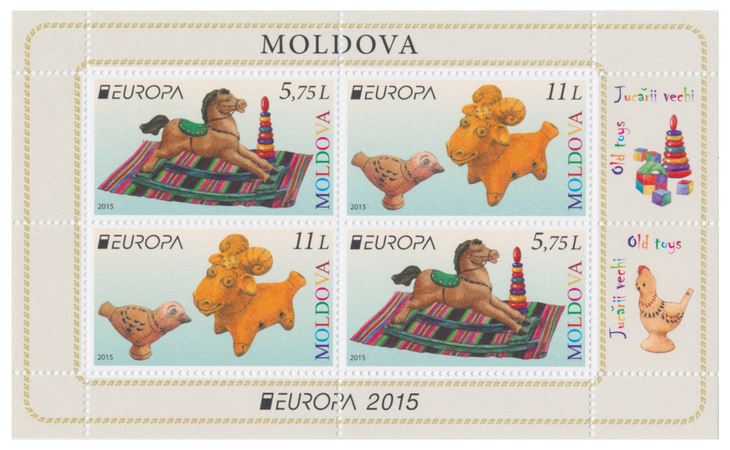

Stamps

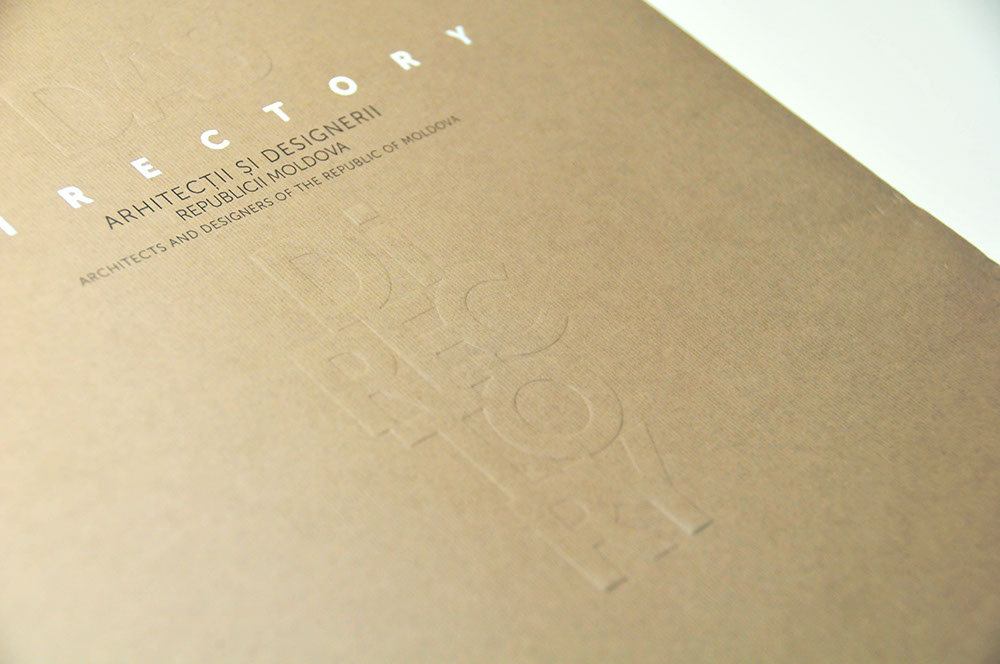

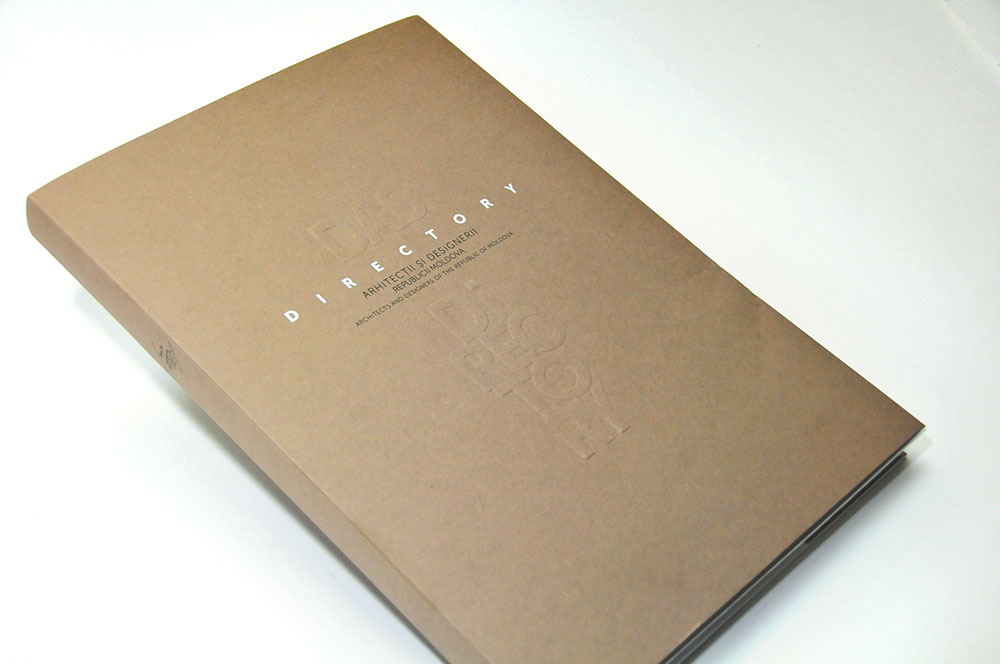

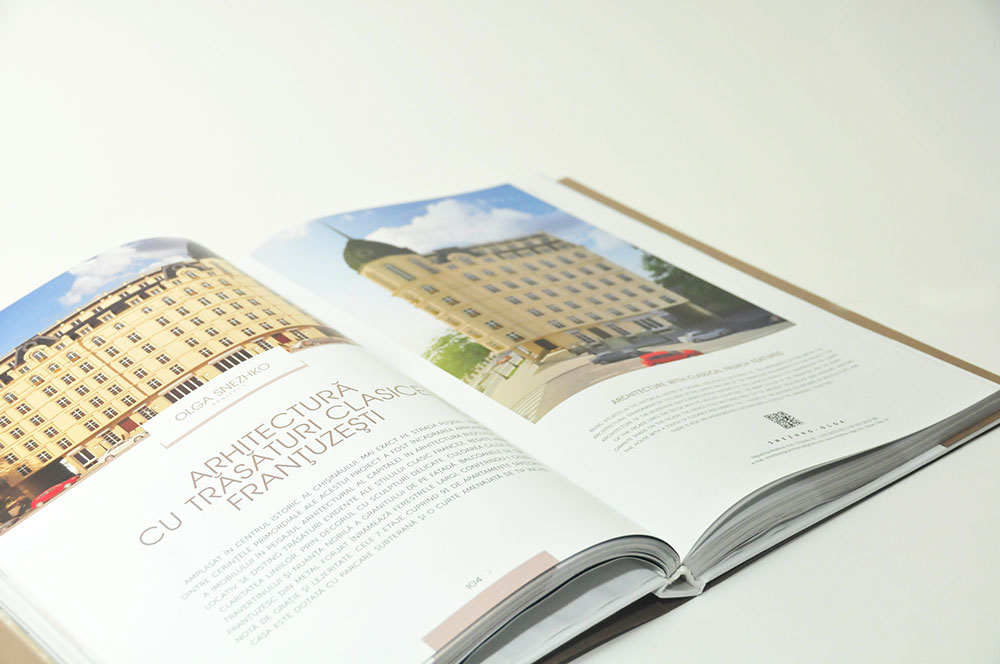

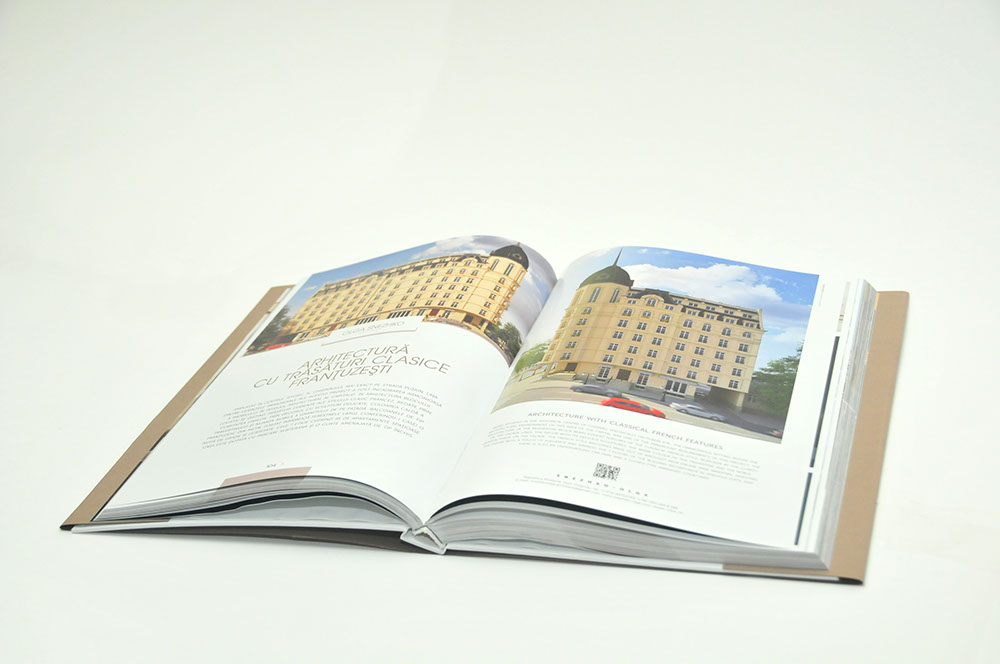

Books

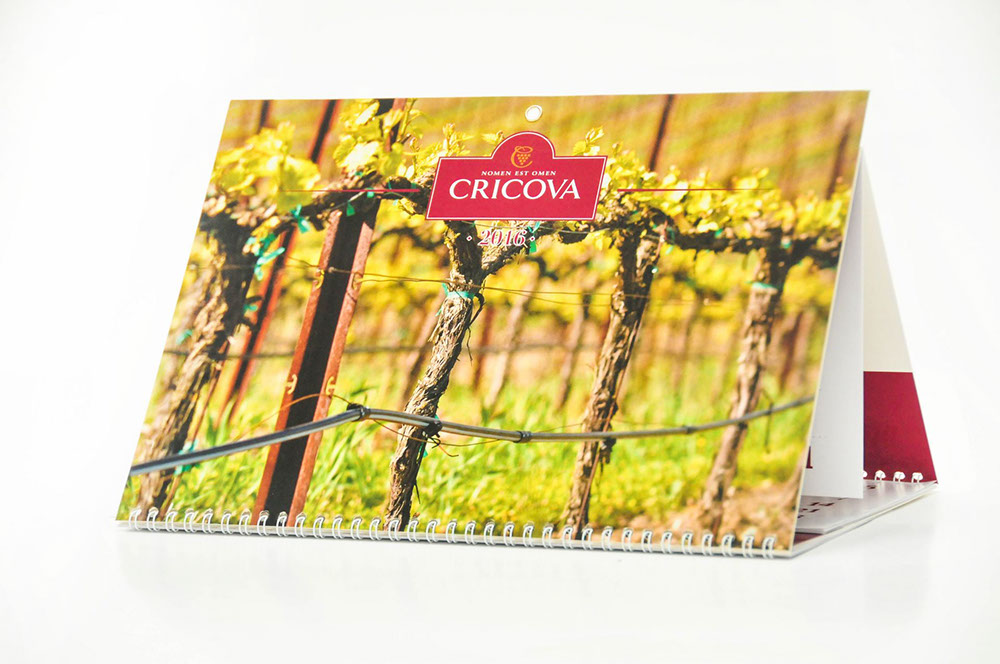

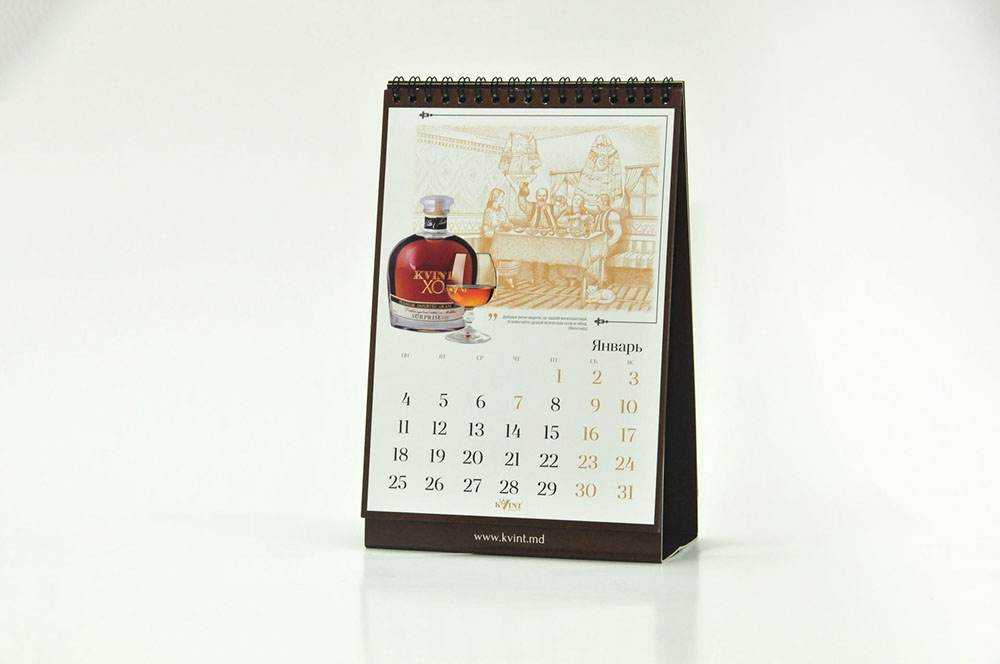

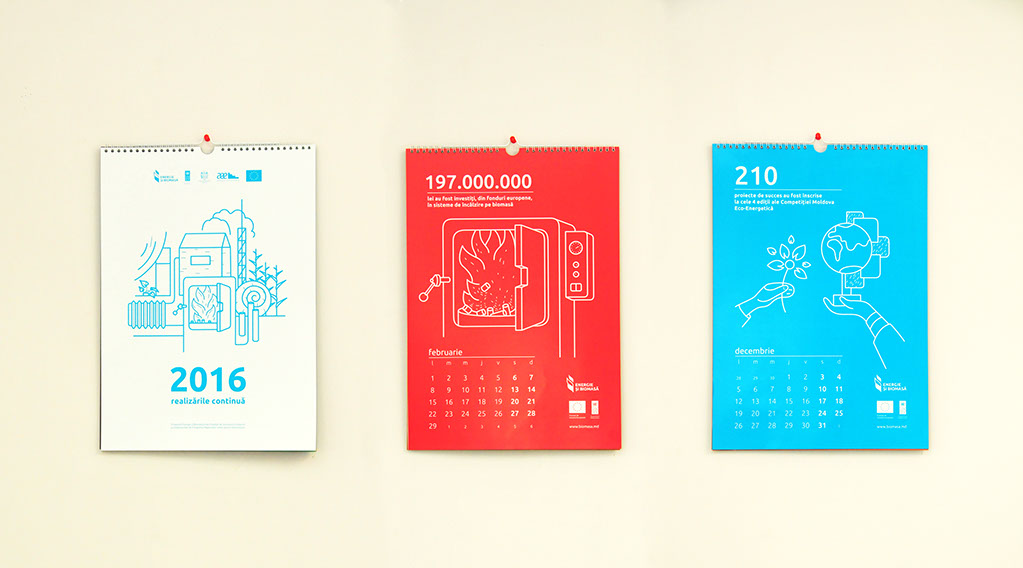

Calendars

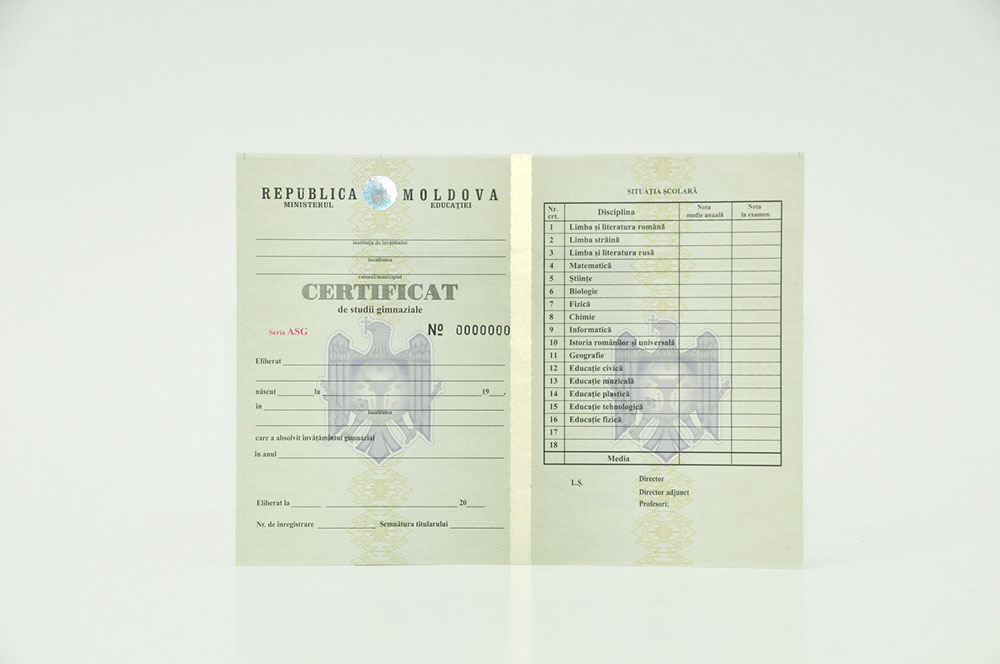

Documents with certain degree of security

735

Completed orders

96

Happy customers

15

Years of experience

19

Professional employees

92

Successful joint projects

HIGH-QUALITY PRINTS

15 years of experience, a team of qualified specialists, and continuous improvement of

the production process contribute to well-timed and high-quality order processing.

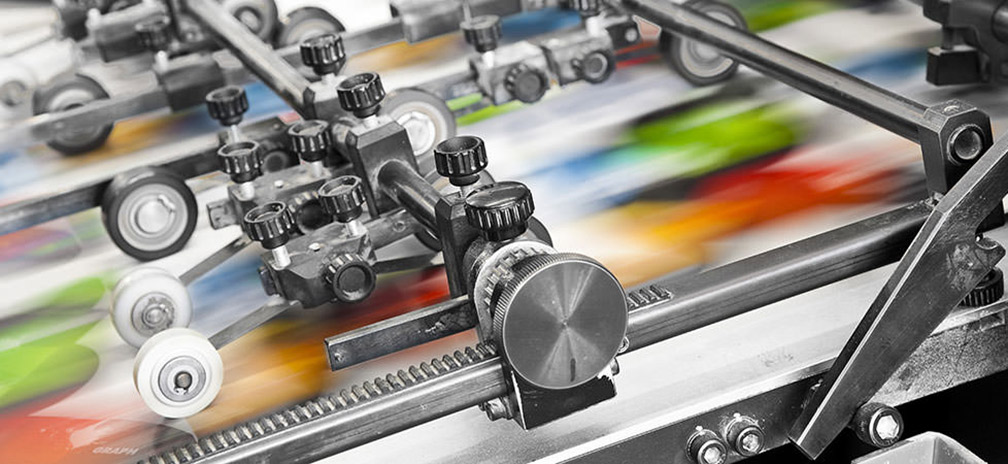

WE USE HIGH-DUTY EQUIPMENT

More than 20 various-purpose units of state-of-the-art printing equipment and devices

allow working with a large range of paper and paperboard.

Nova Imprim Printing House is a modern design and print firm specializing in offset and flexographic printing. Nova Imprim renders a wide range of printing services – both prepress, printing, post press, and page planning and design.

Established back in 2001, the enterprise is well-known in and duly appreciated by the Moldovan market due to the firm’s ability to execute highly sophisticated orders at a top-quality level. Nowadays, the ever-growing staff of the enterprise accounts for about 65 employees.

High-duty printing equipment, a team of qualified specialists, continuous improvement of the production process, mindful approach to every customer – all these are aimed to fulfill orders just-in-time and in a quality manner.

Our customers, both local and foreign, are performing in totally different fields of business: economy, banking and financial operations, food industry, telecommunications, print media, medical and pharmaceutical activity, arts, etc.

Modern imported equipment and the company-exhibited efficiency result in high-quality printed products. More than 20 various-purpose units of printing machinery allow working with a large range of paper and paperboard.

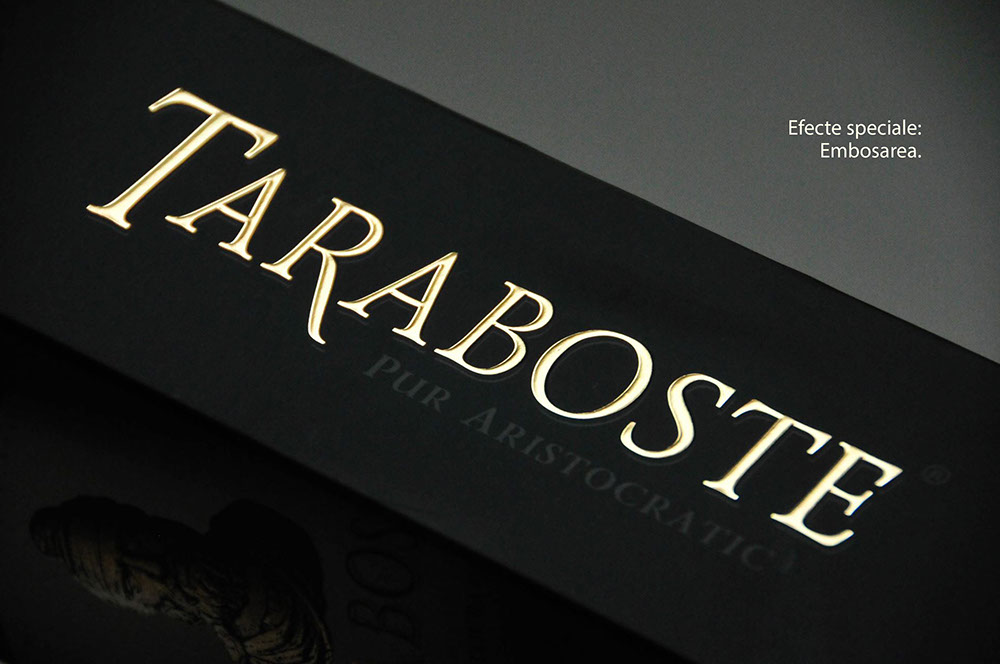

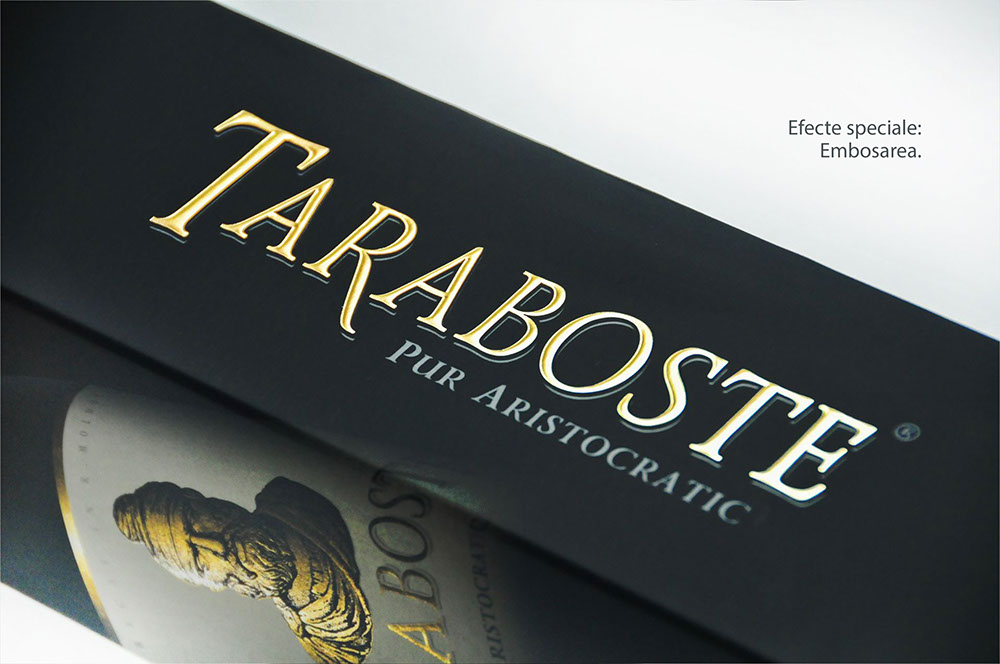

Job is done on the state-of-the-art printing machines of European manufacturers. Post press includes the following types of finish: relief (embossed) printing, foiling, UV-varnishing, different types of bindery, die-cutting, combing, scoring, laminating, etc.

The range of Nova Imprim products is really wide and constantly growing due to our customers. The following are key products we release:

Label – produced using both flexographic (roll-fed), and offset printing. From the standpoint of the variety of patterns and the number of production operations, the label is, perhaps, the most complex product category;

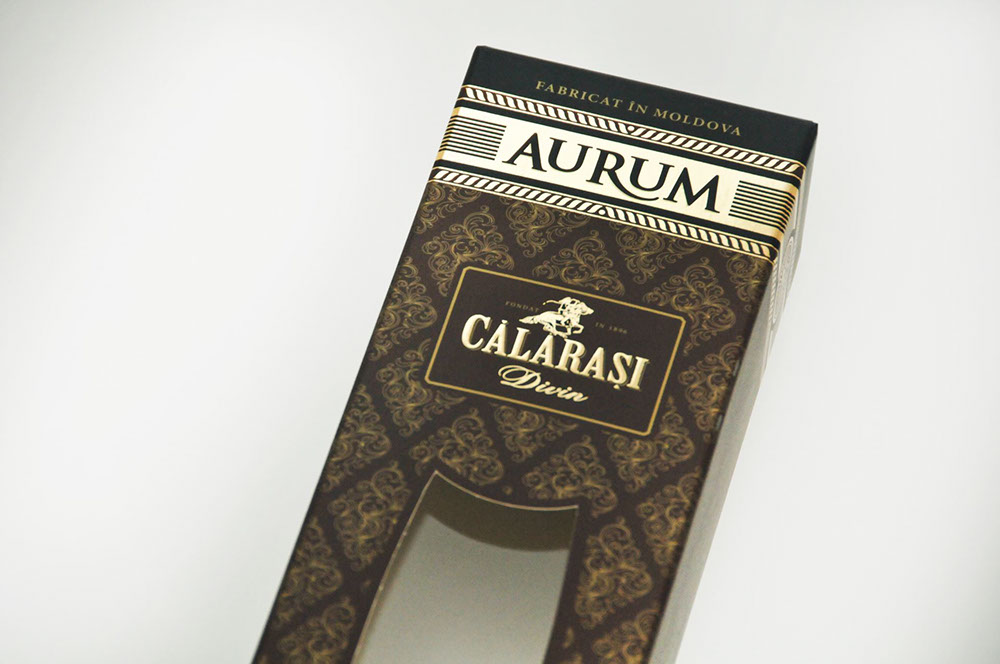

Package (Box) – performs several tasks, and namely: draw attention to the product, highlight its basic properties, and protect it against mechanical damage. Alongside with the label, the package is yet one more product category involving a variety of forms, operations, and graphical solutions;

Books and magazines – non-periodical/periodical edition of at least 48 pages, whose bigger part is written by one or several authors. Pamphlets, catalogues, and albums, containing information from various and sundry fields, can also be referred to this category of products;

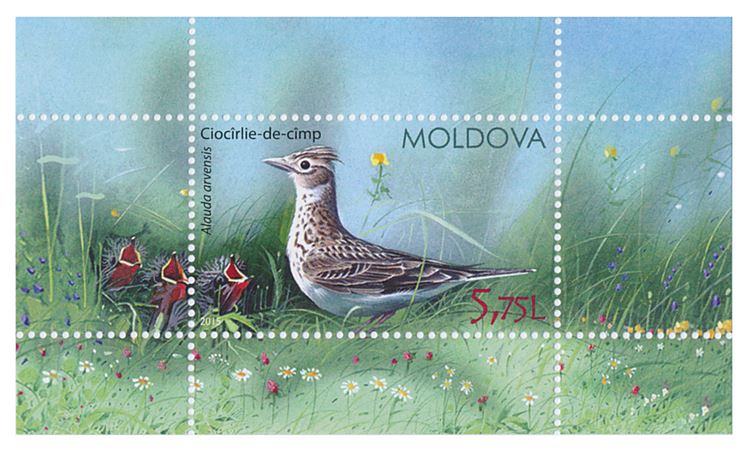

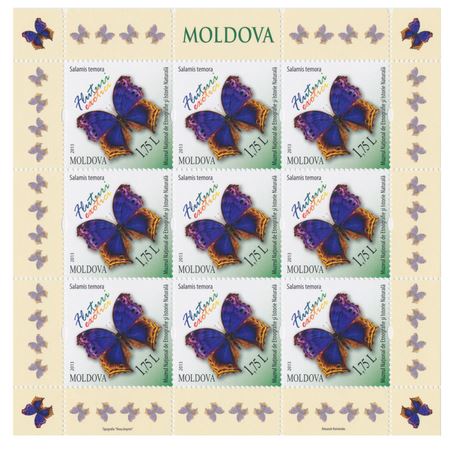

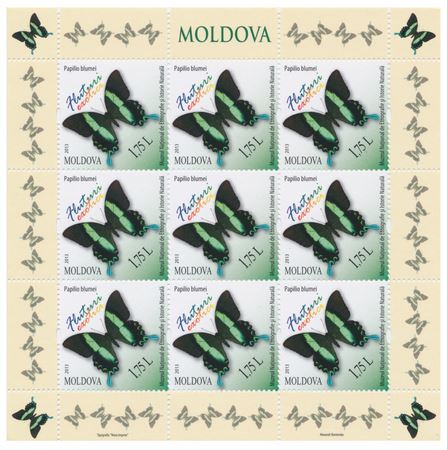

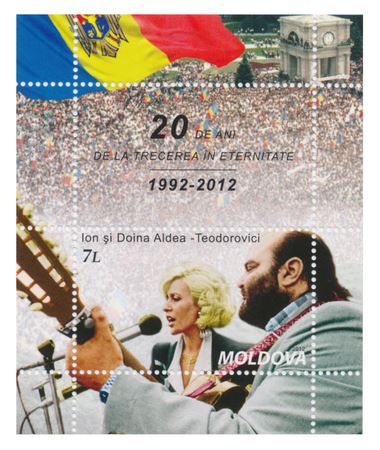

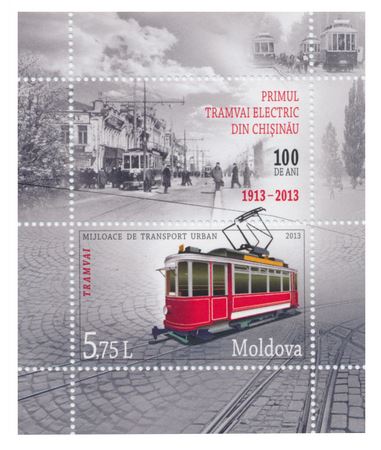

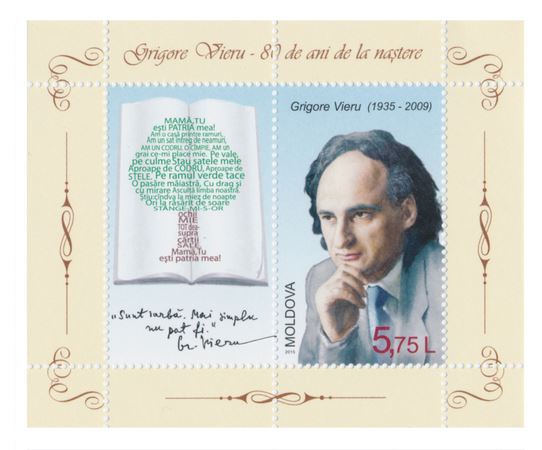

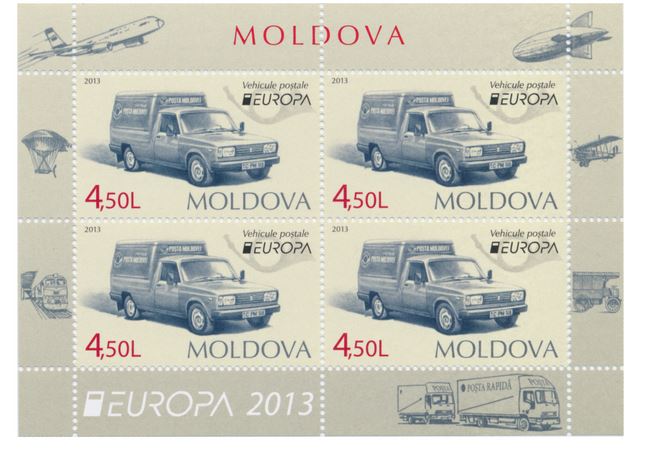

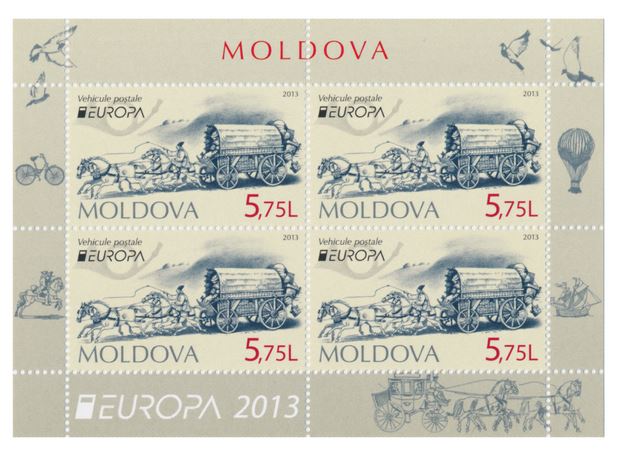

Postage Stamp – a small and mainly rectangular document of value, produced in one, two or more colors. The stamp was invented to simplify the post service payment procedure;

Calendar – a must have home or office accessory. Due to advantageous aesthetic view, a calendar will not only help you orient in time, but can also become an efficient tool to promote ideas or information of advertising nature. Nova Imprim offers a luxurious choice of calendars, depending on customer’s preferences: wall calendars, pocket calendars, desk calendars, posters, etc.

Each of the above-listed product categories can be diversified and refined by means of post press, performed within the printing house: die-cutting, varnishing, laminating, foiling, embossing, etc.

In our work, we use German (HEIDELBERG). The printing house dispose of:

• a CTP Heidelberg Suprasetter A74 for exposure of printing plates

of 760 x 650mm maximal size;

• two Heidelberg four-color printing machines;

Print format max: 740 x 510 mm:

Paper format max: 745 x 525 mm.

For post press, we use equipment of the following manufacturers:

• Heidelberg Eurobind – for binding with the use of hot melt;

• Heidelberg – for UV-varnishing at a max. format of 750 x 520 mm;

• two paper cutters Polar 78XS.

• Heidelberg – for foil embossing:

Print format max: 740 x 500 mm;

Paper format max: 765 x 540 mm;

• VEGA 700 – for gluing boxes.

Other equipment, used for post press finishing of printed products: MBO 66 folding machine, BREHMER thread sewing machine and HOHNER wire stitching machine, selective varnishing machine, die-cutting machine, paper-reeling machine, laminating equipment, perforating machine, etc.

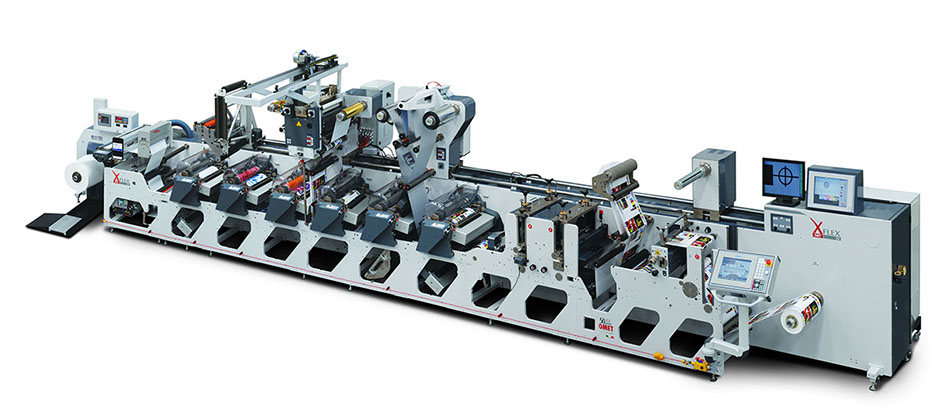

In our work, we use the latest-generation equipment and devices of European manufacturers. The printing house disposes of a flexo machine OMET XFLEX X4 370, which allows printing on a wide range of materials:

• film (OPP, BOPP, PET, PVC,OPS)

• paper, paperboard

• self-adhesive paper

• self-adhesive film

Maximal print width – 365mm, length – 609mm. Color range allowed by this machine: from 1 through 8 colors.

The flexographic machine is equipped with a cold foiling module, which allows printing and inline foiling.

The printing house has equipment for hot foiling and embossing. We also offer stencil package printing services.

ABOUT NOVA IMPRIM

OUR PRODUCTS

OFFSET EQUIPMENT

FLEXO PRINT EQUIPMENT

WE USE HIGH-DUTY EQUIPMENT

More than 20 various-purpose units of state-of-the-art printing equipment and devices

allow working with a large range of paper and paperboard.

POLIGRAFIE DE CALITATE SUPERIOARĂ

15 ani de experiență, o echipă de specialişti calificaţi și perfecţionarea continuă a procesului tehnologic, contribue la realizarea produsului solicitat, calitativ și în termenii stabiliți.

ACCURACY OF EACH AND EVERY DETAIL

Use of efficient color control and management system Heidelberg Axis Control®

allows getting a flawless quality of printed colors.

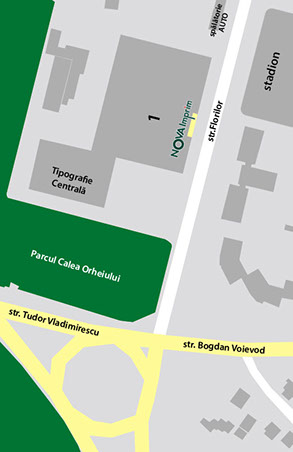

CONTACTS

NOVA IMPRIM SRL

Phone: (+373 22) 494 000

Fax: (+373 22) 433 014

Adress:

1 Florilor street, Chisinau,

MD-2068, Republic of Moldova

Director:

E-mail: roman@novaimprim.md

Phone: (+373 22) 311 192

Council president:

Gheorghe Nichita Revencu

Phone: (+373 22) 311 098

Sales Department

E-mail: ion@novaimprim.md

Phone: (+373 22) 494 000 | (+373 22) 311 097

Bookkeeping Department

Phone: (+373 22) 311 067

ORDER ONLINE

For technical requirements

towards printed files,

please, view the guide below.

Provided that all listed requirements are met, we guarantee the quality of printed products, and this will make you satisfied by cooperation with our printing house.

VIEW TECHNICAL REQUIREMENTS

We accept the following formats of page layouts on PC platform:

Adobe Illustrator (*.ai)

Adobe Acrobat (*.pdf)

Adobe Photoshop (*.psd)

Encapsulated PostScript (*.eps)

Tagged Image File Format (*.tiff)

Adobe InDesign (*.indd)

QuarkXPress

If you use other applications to create a page layout, please contact our specialist to get an advice.

All bitmap images should be presented in CMYK models with the resolution of at least 300 dpi; total area coverage should not exceed 300%.

Use of ”transparent” color is not allowed in bitmap images. Transparent lenses and other transparency-containing images are not allowed – change such to bitmap.

Vector objects with mesh gradient or compound gradients are not allowed (change such to bitmap).

Bitmaps, placed in or attached to the task, should be presented in the following manner:

tiff, psd (CMYK, Grayscale, Bitmap);

eps (save Duotone only as Multichannel. Multichannel files should be saved as Photoshop EPS DCS 2.0. Preview: TIFF (8 bits/pixel), DCS: Single File DCS, No Composite. Encoding: Binary. No Halftone Screen or Transfer functions).

Do not use Pantone colors, if you do not plan to order a printing, which contains additional color. Your page layout should be divisible to the same number of colors you suppose to use for printing of the layout.

When creating the page layout, place the bleed at a 2mm-distance from the background. Besides that, the text should back up at least 2 mm from the bleed. Specify the die-cuts.

For a magazine layout, the bleed should back up from the text by at least 4mm! All options like «Overprint Fill», «Overprint Stroke», indicated in the layout, will be used during printing.

Small black objects (font size up to 20 pt, lines, etc.) should be performed using C:0 M:0 Y:0 K:100 color.

Large black objects (large-font text, large solid plates) should be colored using ”composite black” (C:75 M:60 Y:30 K:100). Publications, created with the use of color palettes other than CMYK (particularly with the use of RGB palette) are not accepted. Do not use in you publication bitmaps in jpeg, gif, or bmp format.

Bitmaps should be either saved inside the publication (embedded image), or linked to it (linked image). When using linked images, do not forget to attach the necessary images to the publication file.

Bitmap resolution: 300 dpi.

All pictures should be provided at the 1:1 scale (bitmaps). If a picture is not a photo, it should not have any background; otherwise the edge of the image should be available. The file should not contain additional channels (only CMYK).

All fonts, used in the publication, should be presented as vector graphics (transferred to curves).

Foiling

Minimal thickness of elements – 0.15 mm. Minimal distance between nearby elements (for instance, under inversion) – 0.25 mm. All foiled elements should be located in a separate layer, which should be placed on top of the rest of the printed elements. Foiling should be marked with special Pantone color. Use of some other elements in the foiling layer (for instance, a printed element getting into the foiling area) is not allowed. In case of outlining this or that printed element by means of foiling, such foiling should be located in the middle of the border of this element.

Embossing

Minimal thickness of elements – 0.5 mm. Minimal distance between neighboring elements – 1 mm. All embossed elements should be located in a separate layer, which should be placed on top of the rest of the printed elements. Embossing should be separately marked with Pantone color. Use of some other elements in the embossing layer (for instance, printed element getting into the embossing area) is not allowed.

Die-cutting

Before starting to elaborate a label design, it is necessary to coordinate the contour of the label as to determine the possibility of die-cutting. When printing labels, the contour should be brought outside the bleed by 2 mm, and the distance between the bleed and the immediate element should not be less than 1.5 mm. The cutting contour should be placed on a separate layer.

Offset Printing

Minimal thickness of elements at inversion:

one color – 0.1 mm

two colors – 0.15 mm

three and more colors – 0.25 mm

Minimal thickness of the printed element:

one color – 0.07 mm

two colors – 0.15 mm

three and more colors – 0.25 mm

In case of failure to meet any of the above-listed requirements, the printing house reserves the right to modify the submitted files or return such for rework!

Test Print

Files shall be printed only after a paper test printing of the layout. The print-out, executed at the printing house and completely corresponding to the e-version of the original paper layout submitted on the data carrier, is signed by the customer and transmitted for subsequent works.

In case all above-listed requirements are met, we guarantee successful transfer of your artwork to the film, and you will be happy you have chosen to collaborate with our printing house.

LOCATION IMAGES:

©2016, NOVAIMPRIM.MD

Made with ♥ and care by DESIGNGRAFIC.MD

-u10292-r-fr.png)